Logistics is the backbone of any online seller’s success.

Thanks to the ever-increasing logistical expectations set by eCommerce beasts like Amazon and UPS, you must run an extremely slick operation to keep your customers happy in these demanding times.

But are you spending too much of your sales in an effort to keep up with maintaining a high-powered shipping machine?

What percentage of sales should you spend on logistics?

Every seller wants to ship products as quickly and as efficiently as possible, but at what point do you stop profits for speed?

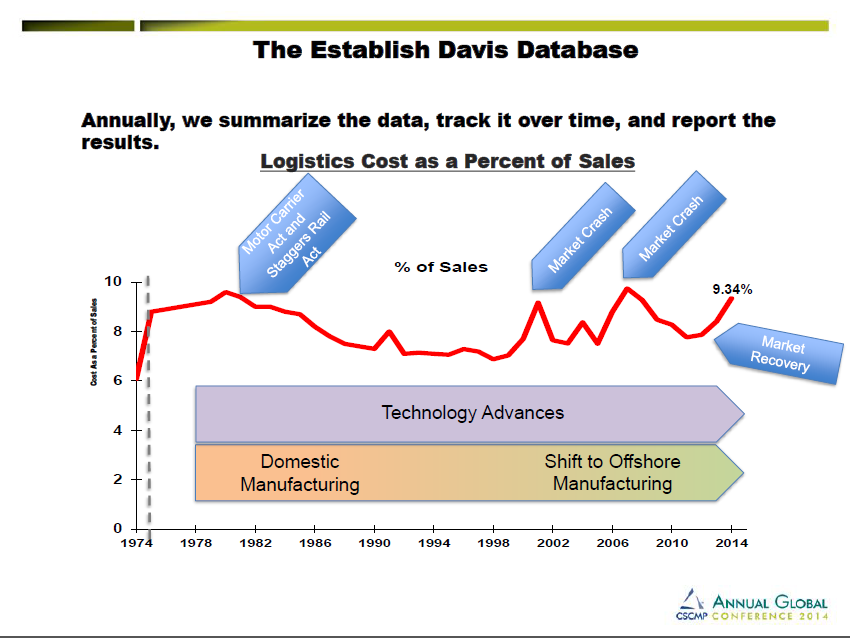

According to logistical data experts Establish Davis, the average in 2014 was 9.34% – an increase of 11% on 2013.

Given the continued economic growth in the US and Europe in 2015, we can expect this average to have grown by at least another 10 percent, if not more.

So, between 10 and 12 percent of sales was the approximate average US companies spent on logistics in 2015.

However, due to the intensive nature of selling online, and particularly selling on Amazon with its associated fees, this figure could be closer to 20 percent for many online retailers.

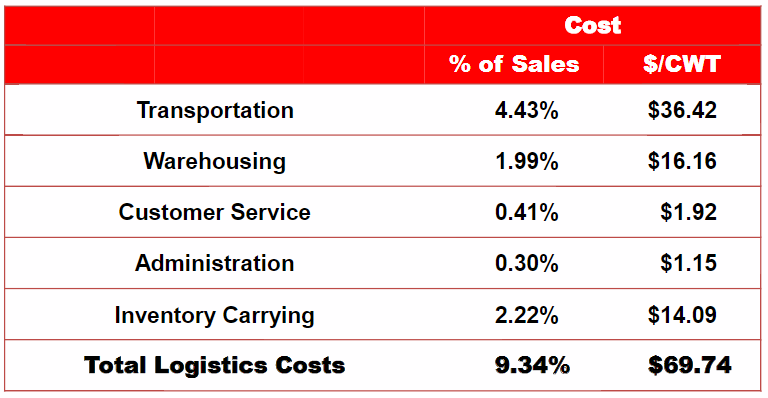

Breakdown of Logistics Costs

Transport, warehousing and inventory account for 90% of all logistics spend.

Here’s how the logistical costs break down on average for US companies.

How does this weigh up against your business spending?

Establish Davis identifies transport, inventory and warehousing as the key areas where companies can reduce costs.

Things you can do to reduce transport costs:

- Mitigate increases in carrier costs by renegotiated your agreements in advance.

- Consider using multiple shipping partners

- Ship by rail instead of truck

- Separate embedded transport costs from landed costs so you can evaluate and control overall transport costs

Things you can to do reduce warehousing / inventory costs:

- Redesign your warehouse to maximize storage capacity and improve efficiency

- Get rid of obsolete inventory

- Reduce your safety stock requirements

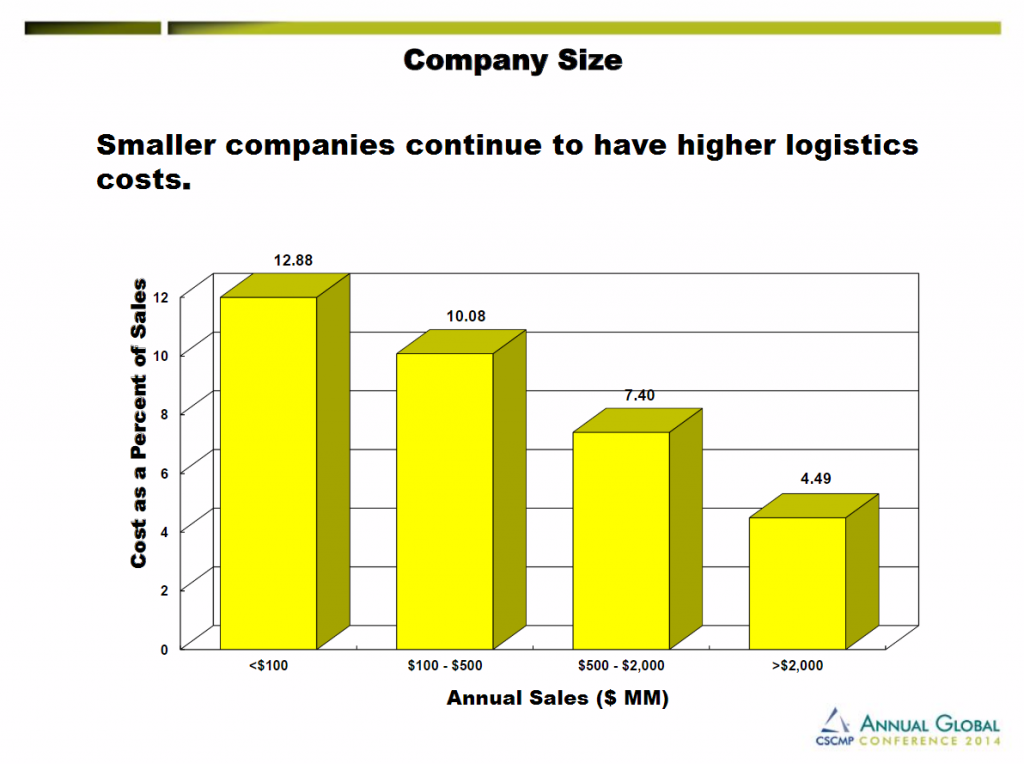

The Establish Davis database also reported that smaller companies tend to have higher relative logistics costs.

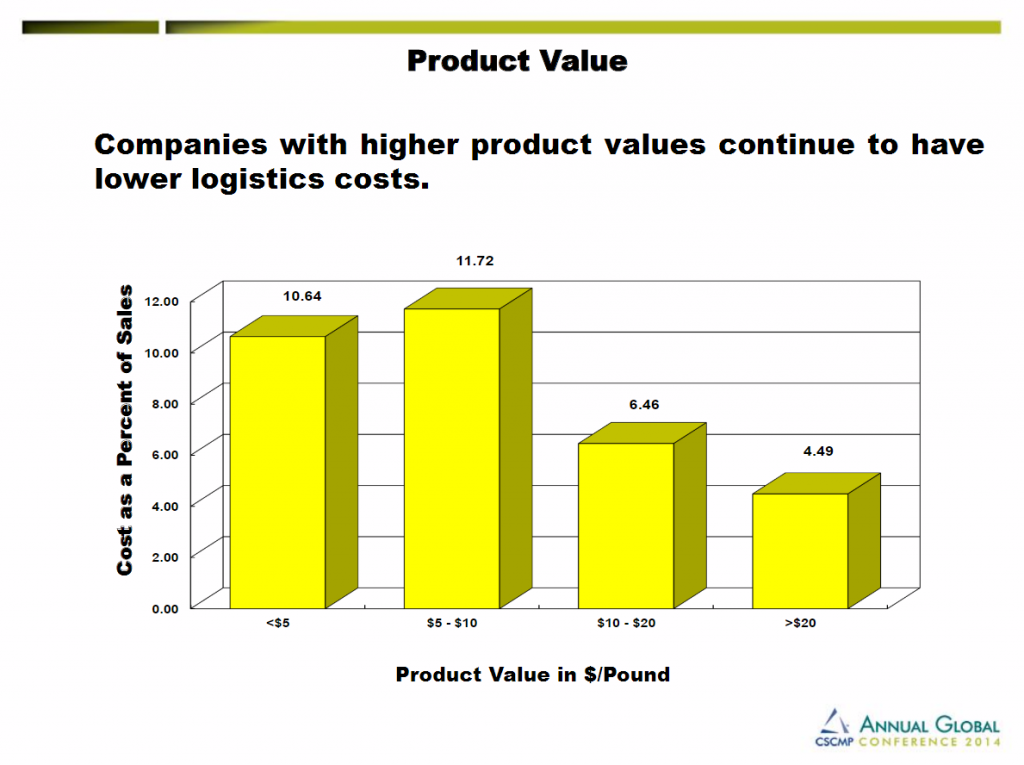

Interestingly, companies selling higher value products have lower logistics costs, presumably due to the ability to command a higher profit against the same logistical cost as lower value items.

4 Key Takeaways

- If your economy is growing, your logistics costs will grow too.

- Take preemptive action to reduce costs.

- Get granular to improve the efficiency of transport, inventory and warehousing.

- Look at selling higher value items to offset the cost of logistics.

Read the full Establish Davis Report.

Got any insights into how to reduce the cost of logistics?Let us know in the comments.